The presence of contaminants in your lubrication oil is detrimental to engines and machinery. Excessive microscopic particles in the lubrication oil lead to corrosion and damage to engine components rather than effectively lubricating surfaces and facilitating smooth processes. It is crucial to measure, control, and eliminate these harmful contaminants to protect the substantial investments made in heavy machinery and equipment within industrial organizations.

Regular oil changes are a commonly recommended practice to avoid the accumulation of impurities. Nonetheless, it’s important to note that even new lubricating oil may contain particles due to improper storage. Additionally, frequent oil changes can be time-consuming, expensive, and contribute to increased waste.

Advanced Oil Filtration Systems

Primary full-flow filters aren’t sufficient in removing contaminants from oil as microscopic particles can pass through the filter mesh. This is where advanced oil filtration comes in. Centrifugal filters in conjunction with primary filters are much more efficient at removing harmful particulates.

ISO cleanliness codes indicate contamination levels, so it’s important for organizations to review ISO codes for oil conditions. Improving ISO codes not only helps save oil but also extends the lifespan of the engine.

this blog, we’ll explore the best way to control and limit contaminants entering engines and machinery.

How can IOW Group extend the lifespan of your engine?

The IOW Group’s centrifugal filters boast unique, patent-protected features that make them 150% more efficient than any other centrifugal filters on the market. These industry-leading centrifuges are specifically designed to prevent cross-contamination between clean and dirty oil. By incorporating bowl disc technology, they achieve superior separation, effectively removing even the smallest contaminants. When paired with CentriClean remote monitoring units, they ensure optimal reliability and efficiency. The IOW centrifugal separator significantly enhances processes, helping your organization meet ISO cleanliness code targets.

IOW Group’s centrifuges consistently outperform the competition by achieving ISO cleanliness codes two to three levels better.

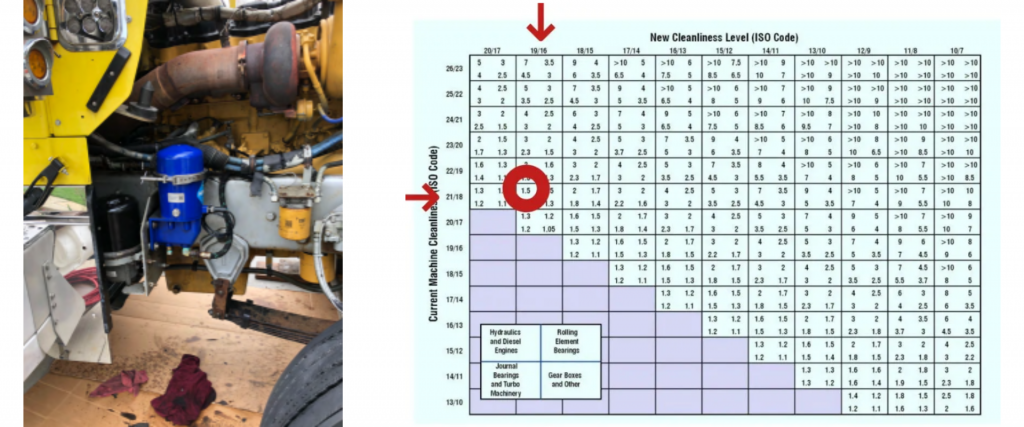

Installation on a CAT 3406 Engine

Recently, a customer approached us seeking to improve the oil cleanliness for their Caterpillar 3406 engine. The initial ISO cleanliness code was 21/18/12, and we knew that by installing an IOW centrifugal oil separator, we could make a significant difference. We installed an IOW MP090 centrifuge filter, and the results were impressive—the final ISO cleanliness code improved to 19/17/12. Using an engine life extension calculator, we determined that the lifespan of the Caterpillar 3406 engine had increased by 1.5 times. The equipment owner was thrilled, knowing that their investment was now well-protected and that the engine would last much longer. Investing in an oil centrifuge today could greatly extend the life of your engine in the long run.

Upgrade your oil filtration system today by contacting IOW Group.